Description

Small Size Mini Right Angle 1: 1 Ratio Jtp65 Spiral Bevel Gearbox

The main components of the small mini right-angle 1:1 speed ratio spiral bevel gearbox adopt international standard materials: the main components are spiral bevel gears: high-purity solid alloy steel material, carburizing process, surface hardening and grinding in pairs for intersecting shafts, low-noise grinding Helical teeth, high rigidity and wear resistance. The input shaft and output shaft: Quenched and tempered alloy steel material, strong suspension heavy load capacity, with key and keyway. Custom stainless steel, chrome-coated, or other corrosion-resistant coatings. Customized spline shaft, keyless and keyless shaft. Housing: high-rigidity cast iron, custom aluminum, stainless steel, electroplating, or other corrosion-resistant paint. Bearings: Heavy-duty input and output shafts, ball bearings on hollow input shafts for motor flanges, custom reinforced bearings for higher radial and axial loads.

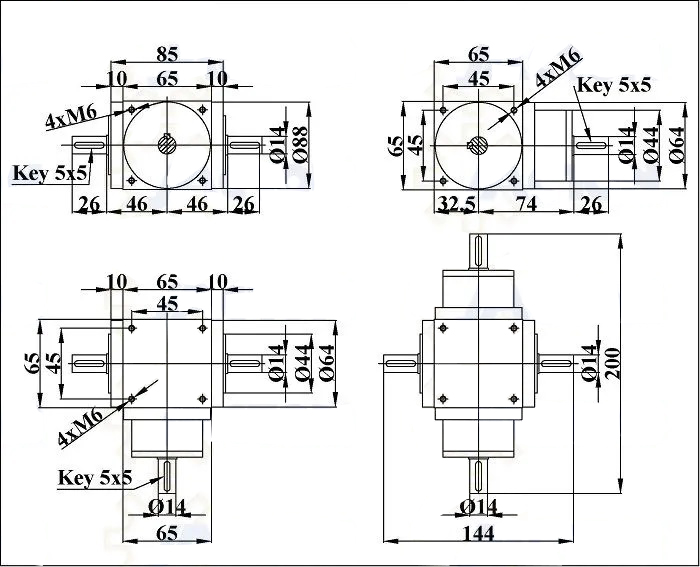

Small Size Mini Right Angle 1:1 Ratio JTP65 Spiral Bevel Gearbox Dimension Drawing

Tiny Dimension Mini Right Angle one:1 Ratio JTP65 Spiral Bevel Gearbox Functions:

1. Optimum allowable torque 19.1 Nm, Highest allowable energy 1.87 kw, maximum allowable input or output pace 1500 rpm.

2. Bevel gears ratios one:1, JCPTize 2:one. Transmission efficiency up to 94-98%.

3. Used in pairs of spiral bevel gears to transmit rotary movement, mechanical electricity, and torque.

4. Cubic condition, universal mounting positions, can be very easily mounted in any path.

5. Reliable shaft as normal. JCPT hollow shaft, motor adapters like IEC flange, and many others.

6. 2-way, 2-way reverse, 3-way, three-way reverse, four-way, and four-way reverse configurations as common.

7. twelve sorts of push shaft arrangements and rotating instructions. Note: travel shafts can be rotated in both clockwise and anti-clockwise rotation directions.

8. Mounting positions: horizontal mounting, overhung mounting, wall mounting.

9. Lubrication depends on output pace. Standard is grease lubrication that is routine maintenance cost-free.

10. Large efficiency, large transmission capacity, minimal backlash, noiseless operation, reduced operating temperature, and prolonged service life.