Description

Post Hole Digger Gearbox

Post hole diggers are agricultural tools used for digging holes in the ground, typically for fence posts or planting trees. These diggers are equipped with gearboxes that are responsible for transmitting power from the engine to the augers that do the actual digging.

Post hole digger gearboxes are typically compact and rugged, designed to withstand the harsh conditions of agricultural work. They are generally manufactured from high-quality materials such as cast iron or aluminum and are sealed to prevent dirt and debris from entering and damaging the gears.

Most post hole diggers use a single-stage gearbox, which provides a direct reduction in speed and increases torque. Some advanced models might use two-stage gearboxes, which offer even greater torque capacity and better efficiency.

The output shaft of the gearbox turns into a spiral-like auger, which is used to cut into the soil and remove it. The auger diameter is a crucial factor to consider when selecting a post hole digger, as it determines the size of the hole that can be dug.

Post hole digger gearboxes require regular maintenance like any other mechanical component. This includes checking the oil level and changing the oil periodically, as well as inspecting the gears for wear and damage. Proper maintenance prolongs the life of the gearbox and ensures optimal performance.

| Description |

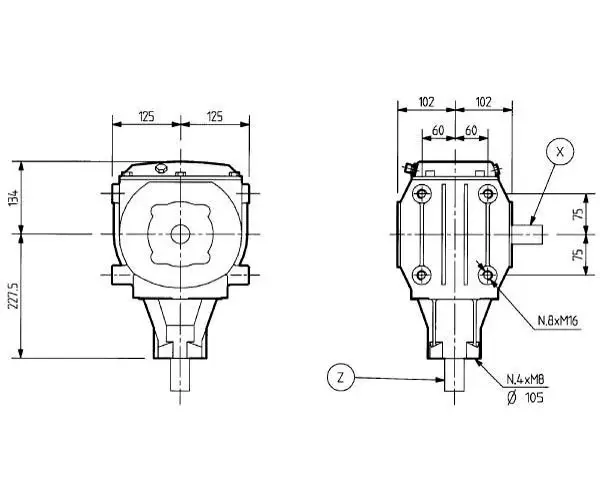

Post Hole Digger Gearbox – Replacement of Comer Code T-22F speed reduction

|

|

|---|---|---|

| Application |

|

|

| Consists of |

|

|

| Technical information |

|

|

| Contains oil |

No

|

|

| Capacity and oil type |

3,3 GL-5 80W-90 l

|

|

| Gear arrangement Increasing |

23 – 24

|

|

| Gear arrangement Reducing |

3 – 4

|

|

| Input power kW / HP Increasing |

72.1 / 98 kW/HP

|

|

| Input |

540 r/min

|

|

| Input shaft Increasing |

Y

|

|

| Input shaft Reducing |

Z

|

|

| Material housing |

Cast iron GG25

|

|

| Input power KW / HP Reducing |

60.4 / 82 kW/HP

|

|

| Output Torque DaNm |

199.5 daNm

|

|

| Output Torque DaNm Increasing |

64 daNm

|

|

| Oil |

500 h

|

|

| Ratio Increasing |

1: 1,93

|

|

| Ratio Reducing |

1,93: 1

|

|

| Shaft Y |

1 3/8″ (6) (B)

|

|

| Shaft Z |

1 3/8″ (6) (D)

|

|

| Weight |

29 kg

|