Description

What Are Heavy Duty U Joints?

Heavy-duty universal joints are high-quality joints for a variety of standard applications with medium loads and RPM. They feature a friction (sliding) bearing design with large and small pins and snap rings. Made of high-grade alloy steel, they offer greater durability and better performance than standard industrial-grade models. Heavy-duty U-joint components are selectively heat-treated, precision machined and ground to exacting tolerances. Heavy-duty universal joints provide excellent service life for demanding applications. All joints are available with or without a lubricant retainer.

Features of U Joints:

- Breaking Torque: Single Joint 11-12,429 N-m, Double Joint 10-11,186 N-m

- Operating Speed: Up to 1000 RPM (depending on lubrication)

- Friction (slide) bearing construction

- Large-pin small-pin design with snap ring

- Advanced Alloy Steel

- Hardened and ground lugs, pins, and blocks

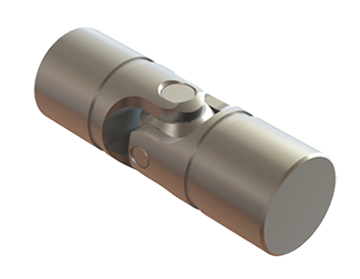

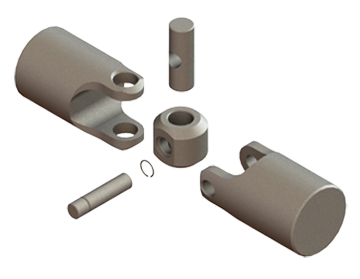

Heavy Duty Single Universal Joint – Exploded View Heavy Duty Single Universal Joint

Heavy Duty U-joint Custom

Heavy-duty U-joints are a critical component of the drivetrain that transfers power from the engine to the wheels. They are commonly used in high-performance vehicles, heavy trucks, and off-road vehicles.

Custom heavy-duty U-joints can enhance its strength, durability, and performance. Here are some possible customizations:

Materials: One way to increase the strength of U-joints is to use high-strength materials such as chrome molybdenum steel or 300M alloy steel. These materials can significantly improve the performance of U-joints in high-stress applications.

Dimensions: Larger U-joints allow for greater torque and power. Custom U-joints are sized to help meet the specific needs of a vehicle or application.

Lubricate: Standard U-joints are generally not lubricated, which can lead to premature wear and failure. Custom U-joints with grease fittings will ensure proper lubrication and prolong their life.

Seals: Dirt and debris can damage the gimbal bearings, leading to failure. Customizing your u-joint with additional seals can help prevent this type of damage and prolong the life of your u-joint.

Snap Rings: Adding extra snap rings to U-joints can help them handle greater torque and prevent them from disassembling under high stress.

It is always essential to consult a professional before implementing any customization to ensure proper installation and optimum performance.

If you have a custom request, you can contact us and one of our professionals will get back to you within 24 hours.