Description

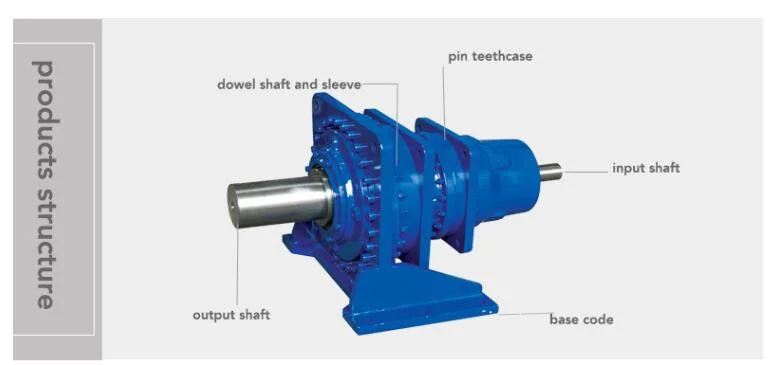

Brevini Flange Input Planetary Gearbox

Brevini flange input planetary gearbox is an industrial gearbox designed with flange input. It is widely used in applications such as conveyors, mixers, cranes, and other power transmission systems.

This type of gearbox uses planetary gears, and its arrangement can be evenly assigned to the load. The input shaft is connected to the solar wheel, and the solar wheel drives the planet’s gear to rotate around it. The planetary gear is fixed by the planet frame and then driven by the ring gear. As a result, the speed of speed and torque enables the gearbox to provide high-power transmission capacity while reducing the size and weight.

Brevini flange input planetary gearbox design is used to handle high loads and high-speed operations, making it an ideal choice for heavy applications. In addition, they have various sizes and ratios to meet different torque and speed requirements.

In general, the Brevini flange input planetary gearbox is a reliable and efficient solution that is suitable for harsh industrial applications that need to provide high-power transmission capabilities in a compact design.

Brevini Flange Input Planetary Gearbox Reducer Female Splined Shaft Output

1. Ratio range: 3.15-9000

2. Enter electrical power: .twenty five-55KW

3. Allow torque rang: ≤ 800000N. M

4. Output pace: .425-445 r/min

5. Structure manner: Likelihood of the flange, foot, or shaft mounting solutions

The attribute of the Brevini Planetary Equipment Reducer :

1. The extensive and broad choice from N Series for Industrial use

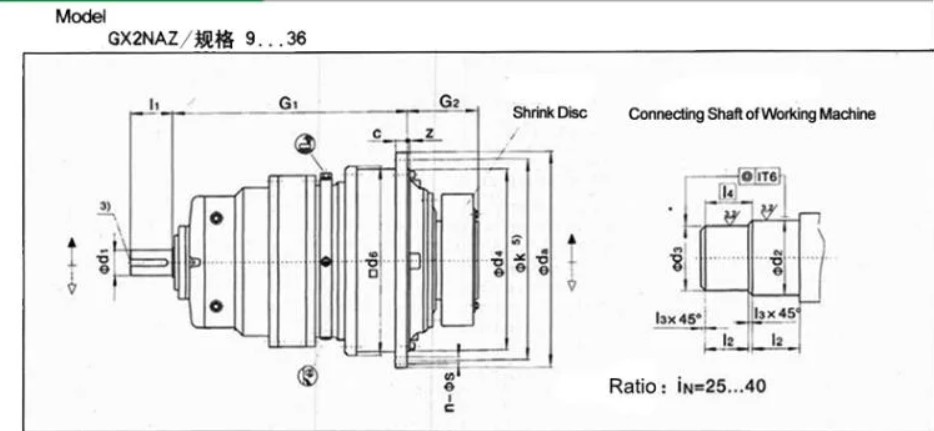

2. Lower-velocity shaft arrangement: Cylindrical with critical hollow shaft, splined or hollow, with shrink disc or hollow shaft splined

3. A precise and rigid nodular cast iron casing

4. High quality, low noise normalization, good quality.

5. High-quality and reliable performance, load capacity, and shaft bearings with a reduced-pace

Knowledge Sheet :

| Torque selection | 1000 … 540000 Nm | Enter | IEC Flange |

| Mechanical score (n1 = 1500 min-one) | up to 200kW | Electric motor | |

| Gear ratios | 3. fifteen … 5000 | Strong enter shaft with or without admirer cooling – inch or metric dims. | |

| Equipment unit variations | In line | Applicable AC motors | Integral motors and brake motors |

| Proper angle (with bevel equipment set) | IEC-normalized motors and brake motors | ||

| Mounting sort | Foot | One and twin-speed motors | |

| Flange mounted | Main brake characteristics | DC and AC provide | |

| Torque-arm | More quick brake reaction by means of an electronically controlled rectifier | ||

| Output shaft alternatives | Strong shaft | Major motor options | Thermistors and thermostat sensors |

| Splined shaft | Independent compelled cooling | ||

| Female splined shaft | Line driver and drive-pull incremental encoder | ||

| Hollow shaft with shrink disc |